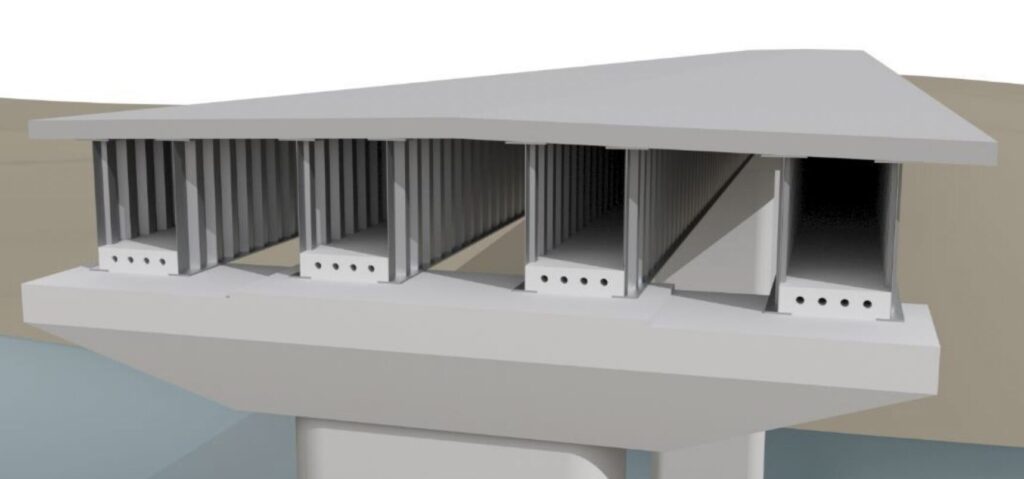

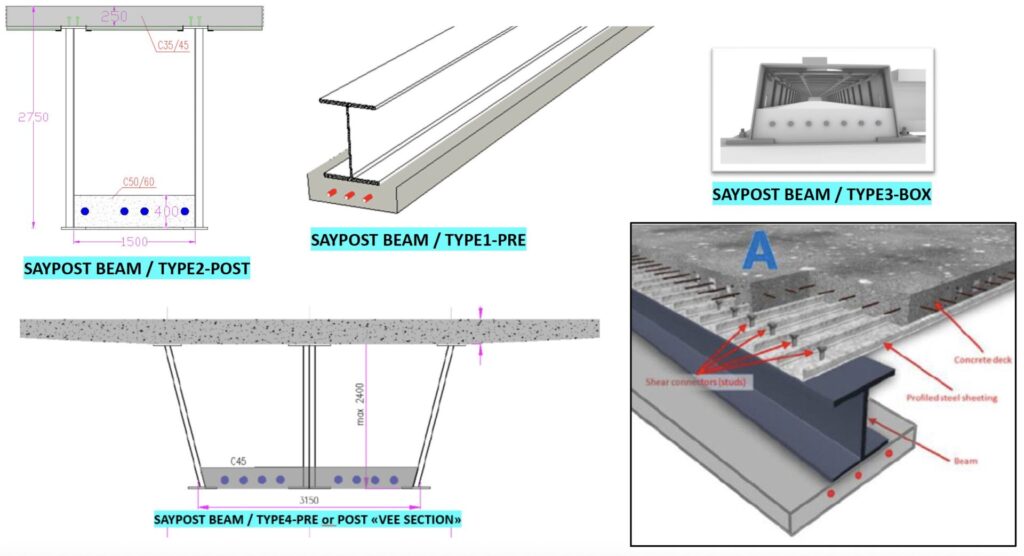

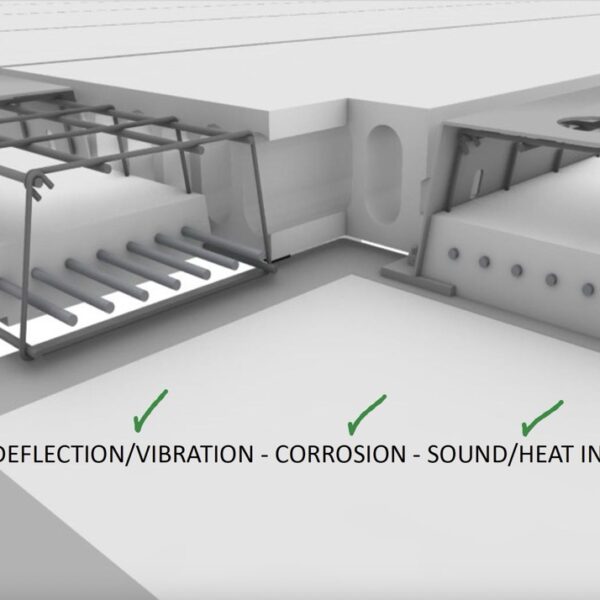

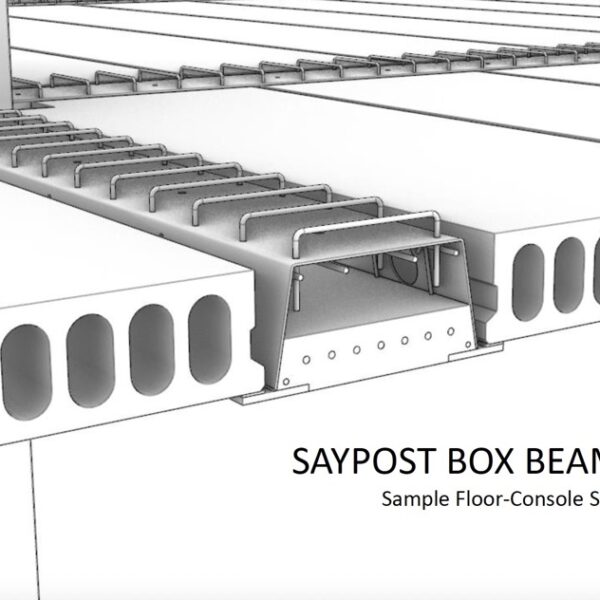

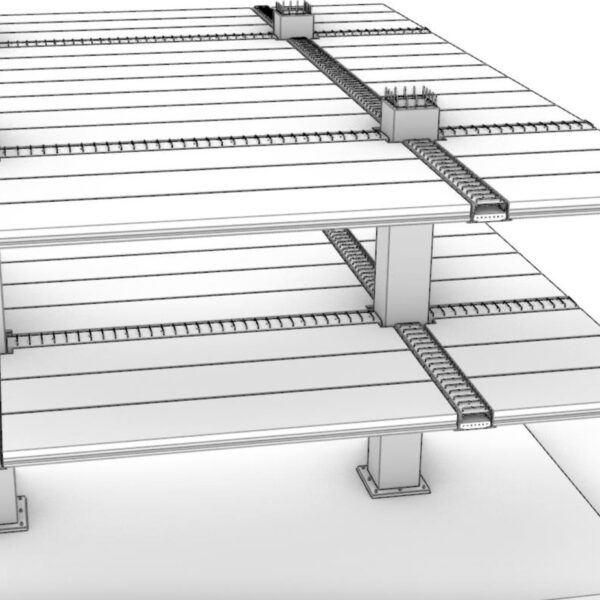

We can design the core and column sections of the structures as Classic Reinforced Concrete, beam & floor system as SAYPOST-BEAM. Especially in Earthquake areas and High-rise buildings, thanks to this we provide safety and economy together. Without the need for additional columns between the core and the facade, the 9-20m wide span with the SAYPOST-BEAM system gives the architect a chance to make more flexible solutions. Due to this, the architecture of the single tower type buildings which are used for different purposes as Car Park, Entrance-Office-Hotel-Residential buildings on the same line makes carrier compatibility more comfortable. Cross section height can be achieved at low heights. In the cladding made with the SAYPOST-BEAM system, the DEFLECTION-VIBRATION comfort is better than the classical constructions. FIRE PROTECTION and CORROSION comparing to the classical steel construction can be achieved much more economically, in this case showing similar behavior with reinforced concrete structures. With SAYPOST-BEAM slab system thanks to BODY SPACES; Ventilation, Mechanical-Electricity, Fire-Sprinkler, Air, Water utilities are possible to be solved at the BEAM LEVEL. This is a much higher usage area than reinforced concrete or steel beamed flooring systems. Especially in the buildings with height limit, it allows to provide the desired net useful height.

Saypost Beam Technology

It is a new generation beam system strengthened with reinforced concrete plate and pre-stressed cable harness. After the site installation, it works as a composite beam with casting deck concrete.

- Wide spans,

- Single or continuous beam & tapered continuous beam.

- Pieces by pieces manufacture in a factory – easy transportation.

- Can be combined with bolts on the site.

- It has high fatigue strength.

- Better corrosion & durability

- 3-5 times lighter than reinforce beam solutions,

- Can be vertical & horizontal curved bridge

Saypost Beam elements can be produced as Curvilinear. It is made in parts with bolts attached so that it can be easily transported all over the world.

Thanks to this feature, we can produce bridges with a span of up to 200m in the factory environment.