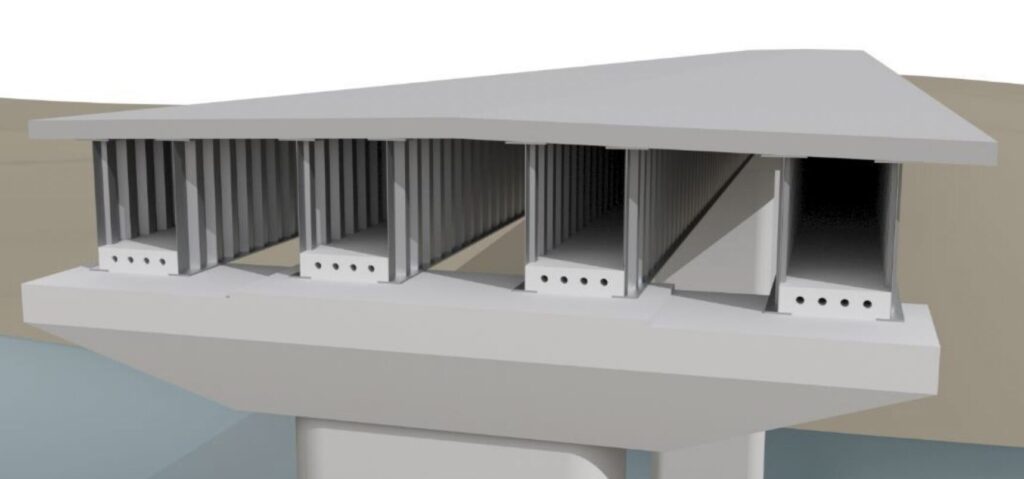

We deliver advanced bridge and viaduct systems engineered to achieve clear spans from 25m to over 150m. Our innovative SAYPOST-BEAM (Prestressed-Posttension Beam) technology can effectively double conventional span lengths, significantly reducing the number of supports required and shortening project timelines. This system integrates seamlessly with earthquake isolators, which decreases the horizontal loads transferred to the supports and foundations. The result is a more efficient, resilient, and economical structure compared to traditional methods.

These advantages deliver substantial cost savings, especially in challenging conditions. Our systems are ideal for viaducts with high supports or on ground requiring deep pile foundations, where our SAYPOST-COLUMN technology also excels. Furthermore, our manufacturing process requires no additional moulds, lowering costs and accelerating production and assembly speeds. With versatile installation methods suited for any terrain—from natural land to river crossings—we provide faster, more affordable viaduct solutions without compromise.

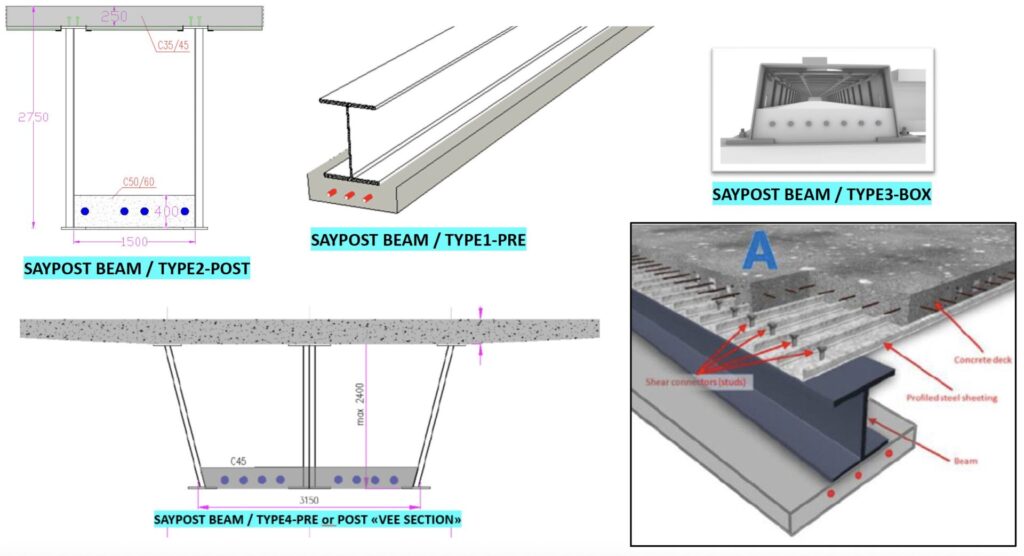

Saypost Beam Technology

It is a new generation beam system strengthened with reinforced concrete plate and pre-stressed cable harness. After the site installation, it works as a composite beam with casting deck concrete.

- Wide spans,

- Single or continuous beam & tapered continuous beam.

- Pieces by pieces manufacture in a factory – easy transportation.

- Can be combined with bolts on the site.

- It has high fatigue strength.

- Better corrosion & durability

- 3-5 times lighter than reinforce beam solutions,

- Can be vertical & horizontal curved bridge

Saypost Beam elements can be produced as Curvilinear. It is made in parts with bolts attached so that it can be easily transported all over the world.

Thanks to this feature, we can produce bridges with a span of up to 200m in the factory environment.